Motorcycle Tires 101

Round, and usually black.

Unless you’re a professional or amateur motorcycle racer, or are otherwise ultra-conscious of your bike’s tires, a safe guess says that round and black is most of what many motorcyclists know – or care to know – about the tires mounted to the wheels of their trusty two-wheeled steed.

Yet, ignorance of tire knowledge is understandable to a point. Once the tires are purchased, mounted to the wheels and inflated, their presence is easy to forget: tires produce only a small amount of noise when rolling at speed, are difficult to see while riding, and the only routine care necessary in most cases is checking for proper inflation.

Many tires are designed to last for thousands of miles of trouble-free service with very little upkeep. Understanding some basic tire knowledge will help you better care for your rubber and make you an informed consumer when the time comes to get some new round, black hoops.

Motorcycle Tire Basics

The simplest route to choosing new tires is to install tires identical to those you’re replacing. This is fairly easy if you’re riding a motorcycle manufactured within the past 10 to 15 years.

Many motorcycle tire companies today still produce tires that are either identical to those you’re replacing, or are suitable replacements designed to work with your specific model of motorcycle. At the very least, if an identical replacement isn’t available, tire manufacturers will offer a number of tires that will work in the broader category of your type of motorcycle, i.e. the 600cc sportbike class or the heavyweight touring motorcycle segment.

However, best practice is to select replacement tires identical to those currently on the motorcycle.

A fact too infrequently mentioned is that motorcycle manufacturers will go to great lengths to develop a motorcycle’s handling performance around a tire of particular construction.

Motorcycle companies will work directly with one, perhaps two, tire manufacturers to produce a tire set that will allow the motorcycle to perform exactly how the bike maker intended. Selecting a tire with different dimensions, even marginally different than the tire fitted as original equipment, can dramatically alter the way a motorcycle steers, stops or accelerates.

Often these changes in the bike’s performance are for the worse, although there are instances where handling improves when a tire slightly different than the original is used. Knowing your motorcycle intimately will help you determine if the motorcycle manufacturer intended a specific tire for your machine.

An original equipment tire is usually costly to replace, especially when purchased from a motorcycle dealer that sells the same brand of motorcycle for which you’re looking to fit new tires. So, are you left with no option but to pay the piper? Not necessarily.

Like many things in life, with bike tires there are often exceptions to the rule; despite motorcycle makers designing around a specific brand and model of tire, as a rider you have options in tire choice, a choice which is often influenced by the coins in your purse.

The primary piece of data needed to begin your tire search is the exact model and year of your motorcycle. With this seemingly trivial bit of information a dealer, large motorcycle parts and accessories retailer, or your local independent shop can immediately offer you a number of tire choices from a variety of tire makers. At that point you might choose to select the least expensive tire, and call your job done.

On the other hand you might want to choose between longer wearing tires for increased mileage, or those that provide mileage similar, or slightly less, to your original tire, but offer increased grip performance. Tire makers also design tires claimed to provide a smoother ride, quicker warm up time, or any number of other features that enhance tire quality.

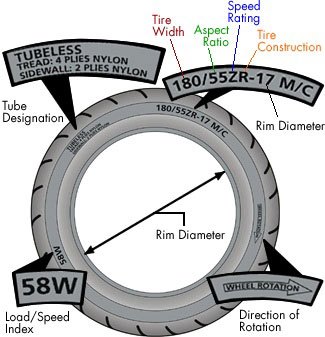

The next step in better knowing the tires that will work on your ride is understanding tire size dimensions. Modern street tires have size data embossed on the tire’s sidewall. Metric sizes generally consist of three numbers arranged in this manner: XXX/XX x XX.

The first number is the tire’s width expressed in millimeters, though the mm designation isn’t printed next to the number. The second number following the slash mark is what’s known as the tire’s aspect ratio. This is the height of the tire’s sidewall expressed as a percentage of the tire’s width – put simply, it’s a ratio of height to width. The final number refers to the wheel diameter (also the inner circle of the tire) expressed in inches.

For the sake of easily understanding how to read a tire’s metric size dimensions we’ll use a common rear tire size found on modern sportbikes: 180/55 x 17.

The number 180 tells us the tire is 180mm at its widest point, while the second number, 55, says that the tire’s sidewall height is 55-percent (roughly 99mm) of the width of the tire. Finally, 17 tells us that this tire is for a wheel measuring 17 inches in diameter. The front tire will use the same sizing convention, but unlike most automobile tires with have matching sizes front and rear, the front tire on a motorcycle is almost always narrower than the rear, even if the particular bike uses identical diameter wheels for front and back.

Of course, a simple look at a motorcycle’s tires will reveal the disparity in widths of the front and rear tires. But in our ever-litigious society tire makers want to ensure consumers, and even professional motorcycle mechanics, know which tire is for the front and rear, so it’s not uncommon to see Front or F embossed on a front tire, and Rear or R embossed on a rear tire.

You’ll often also see a rotational direction indicator to prevent you or the shop from mounting the tire backwards, for lack of a better term, since most tread patterns are designed to work in one direction in order to effectively disperse water from the tire.

Along with the tire’s dimension numbers you might also see a letter or two mixed in. The first letter is the tire’s speed rating, and indicates the maximum speed for which the tire was designed. A second letter may follow the first, indicating type of construction: “R” (radial), “B” (bias belted) or “_” (bias).

If you ride an older motorcycle, particularly some makes of cruisers, your tires might use an alphanumeric convention to relay size info. For example you might see MT90-16 on the rear tire.

Converted to the metric tire dimension system the above rear tire’s dimensions would roughly read: 130/90 x 16. However, many current model cruisers, including those from Victory and Harley-Davidson, now display tire dimensions on bike model spec charts using the metric reading. Your local shop shouldn’t have any trouble helping you find a metric equivalent if your current tires use the alphanumeric system.

| Motorcycle Tire Letter Symbols | |

| Speed-Rating Symbol | Speed Category |

| J | Up to 62 mph (100 km/h) |

| N | Up to 87 mph (140 km/h) |

| P | Up to 93 mph (150 km/h) |

| S | Up to 112 mph (180 km/h) |

| H | Up to 130 mph (210 km/h) |

| V | Up to 149 mph (240 km/h) |

| W | Up to 168 mph (270 km/h) |

| Z | Up to 149 mph (240 km/h) |

| Scooter | Up to 62 mph (100 km/h) |

An additional letter/number combo you might see on the tire’s sidewall refers to the tire’s load and speed index rating expressed as a two-digit number followed by a letter.

Piecing all these numbers and letters together, the information displayed on a tire’s sidewall would look similar to the example tire in the following graphic:

Note that the speed index letter (W) next to the load index number (58) is different than the tire’s Z speed rating designation in the dimensions area. This load/speed index (58W) tells us that when the maximum listed inflation pressure is used the tire may be safely ridden to a maximum speed of 168 mph so long as the tire’s load doesn’t exceed 520 pounds.

The obvious thing to take away from this is that while the tire is rated for speeds in excess of 149 mph, it isn’t designed to do so when burdened to its maximum load capacity, hence the load/speed index indicator.

Other important tire information that falls into that all-too-infrequently-mentioned category relates to type of tire construction, and new/old tire combos.

Referring to our earlier note about how motorcycle manufacturers design their motorcycles with a specific tire in mind, we need to point out that a tire’s construction, whether radial, belted-bias, bias, etc., plays a huge role in a motorcycle’s handling performance. What you need to know here is that, generally, you shouldn’t use a mix of a bias-ply tire and a radial construction tire on the same bike if the bike didn’t come originally equipped as such. Doing so may adversely affect the motorcycle’s handling.

Nearly as important as avoiding mixing tire construction types is installing one new tire instead of two – specifically replacing a new front tire while still using a worn rear. This cheapskate mixing of new versus worn could potentially cause instability in the bike’s handling.

Since a motorcycle’s rear wheel is the driven wheel, it’s not uncommon that the rear tire wears sooner than the front, leaving the front tire with many more good miles. Replacing a rear tire without replacing a front tire that’s still serviceable may be moderately less risky than doing the opposite. But again, employing best practices says replace tires in pairs if you can.

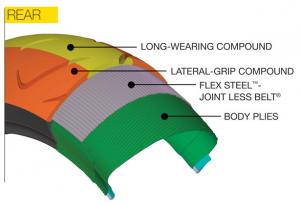

Another component of tire construction involves construction materials (the chemistry of ingredients that make up the tread area) and their arrangements.

A recently popular type of construction is to use two different rubber compounds in the same tire – a longer-wearing center section with a grippier compound in the shoulders of the tire for better cornering performance.

Like anything for sale on the open market, every tire maker producing dual-compound tires, or any tire for that matter, claims it has a unique concoction that makes its tire stand apart from the rest. And some tire makers are currently bucking the dual-compound trend, and instead using a proprietary construction that allows the tire to use a single compound but mimics the performance of a dual-compound tire.

Most dual-compound tires are marketed to the sport and sport-oriented motorcycle segment, including sport-tourers. However some d-c tires are finding their way on to larger, touring type motorcycles.

| Safety Tips for Off-Road and Dual-Sport Motorcyclists |

| 1. Air pressure: Always maintain the recommended tire pressure for the type of terrain on which the motorcycle is being ridden; check the owner’s manual. Underinflated tires may cause wheel damage when ridden on rocky, rough terrain and allow the motorcycle to squirm or wander on smooth, hard terrain. Overinflation may damage the tires and cause an unnecessarily harsh ride. To accurately measure tire pressure, use a standard tire-pressure gauge. 2. Condition: Check for cuts and gouges that may cause air leakage. Also check the tires for missing knobs and excessive wear. 3. Wheels: To avoid loss of control or injury, make sure axle nuts are tight and secure. Grasp each tire at the front and rear and try to rock it on its axle to detect worn-out bearings or loose nuts. There should be no free play or slip as you rock the wheel. Inspect wheels for broken or loose spokes and for cracks on the hub or rim. |

Tires Are Maintenance-free, Right?

Out of sight, out of mind is the attitude most of us have toward tire care. Yet a few simple precautions and checks is all that most tires require. Chief among those checks is your tire’s inflation pressure.

Tires typically don't shed pounds of air overnight. Nevertheless, a weekly check (if not before every ride) of the tire’s air pressure with a good-quality air gauge will only take seconds, and the benefits of keeping the tire within its proper inflation range are numerous.

Other basic upkeep, while not necessary, includes cleaning. A clean tire sidewall can really jazz up the bike; but stick to water and mild soap for cleaning.

Stay away from heavy duty tire cleaning products if you can, and for heaven’s sake don’t spritz on products designed to make your tire look shiny and new – you risk getting the tire dressing product on the tread. By using tire dressing you might have just made your tires ultra-slippery, but you likely won’t realize this until after you and your motorcycle are once again upright.

In this same vein, do everything you can to prevent your tires from prolonged contact with oil and gasoline. Not only are these fluids slick as snot, they eventually cause degradation of the tire material.

If you live in a region of climate extremes, or otherwise don’t ride your motorcycle for an extended period, you’ll want to consider treating the tires on your motorcycle just like a motorcycle shop or large tire retailer would treat tires they store as part of their stock. Proper storage includes avoiding exposure to direct sunlight, extreme hot/cold temperatures, as well as keeping clear of ozone generating sources such as electric motors, battery chargers, generators or welding equipment.

An ideal storage area is clean, dry, well ventilated, and has consistently moderate ambient temperatures. Although you may not use the motorcycle for weeks or months, you should occasionally make a check of the tire pressure for proper inflation levels.

Here are some more important tips on tire inflation and general tire care from the Dunlop tire company:

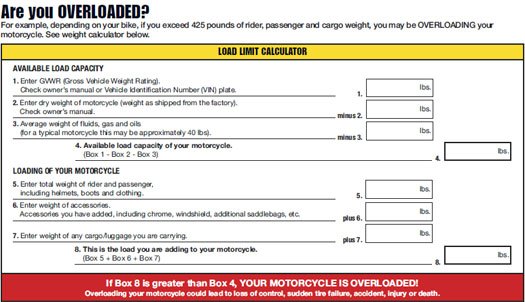

• For fully loaded or dual-riding touring-motorcycle applications, inflate tires to the maximum pressure recommended by the motorcycle manufacturer. And never exceed maximum load capacity indicated on the tire’s sidewall or the motorcycles capacity load found in the owner’s manual. A good rule of thumb is to use whichever maximum load recommendation is lower if the manual or tire sidewalls have different max capacities.

• Underinflated tires can result in imprecise cornering, higher running temperatures, irregular tread wear, fatigue cracking, overstressing and eventual failure of the tire carcass, all of which could lead to, at some point, loss of control of the motorcycle.

• Overinflating tires does not increase load-carrying capacity, but will result in a hard ride and accelerated tire wear in the center of the contact patch. Check cold tire pressure frequently with a good-quality gauge that holds a reading, and always before extended trips.

• Loss of pressure may occur due to worn-out or badly seated valve cores. Check valve cores, and if necessary, tighten for correct seating, or remove and replace them. A metal or hard-plastic valve cap with an inner gasket should be used and installed finger-tight to protect the valve core from dust and moisture and to help maintain a positive air seal.

• Tube damage, as well as cracked rubber tube or tubeless valve stem bases, may also cause loss of pressure. Inspect rim bands, tubes and valves. Replace if damage or cracking is noted.

• Repeated loss of pressure may result from undetected tire damage. Visually inspect tires for punctures, cuts, abrasions, cracks, bulges, blisters or knots. It will be necessary to dismount the tire to complete an inspection for internal damage and any need for repair. Only certain punctures in the tread area may be repaired, and only if no other damage is present.

• Always seek expert inspection of the dismounted tire following curb, chuckhole or other impacts, evidence of penetration beyond the tire surface, bulges or low pressure. You should not continue riding on such tires.

• The appearance of stress cracks in the tread grooves is one indicator of overload and/or underinflation. If you find evidence of tread-groove cracking, you should remove and replace the tire immediately. This damage is permanent and non-repairable.

• Tires with non-repairable damage must not be used again. Damage caused by impacts, penetrations or continued underinflated/overloaded use is progressive and can result in sudden and complete tire failure.

• Always remove tires from service before they reach the tread-wear indicator bars (1/32 of an inch tread pattern depth remaining). Worn/unworn tire combinations and worn tires used in wet conditions can result in deteriorated handling.

• When fitting a new tire on a rim requiring a tube, a new tube should be fitted at the same time. Always check the size markings on the tube to ensure that the tire size appears on the tube. Do not fit tubes in radial motorcycle tires, nor fit radials on rims requiring tubes, unless the tubes bear matching size and radial ® markings.

• Inspect your tires frequently for damage, and always heed warning signs such as vibration, handling instability, rubbing or tire noise that occur during operation of the motorcycle.

Keep The Rubber Side Down (And In Good Condition)

Motorcycle tires have a dual nature: They perform the complex and paramount task of keeping your bike connected to the road, sometimes at silly speeds, yet they demand just a little more routine attention than a pet rock.

Hopefully you’ve come to better appreciate some of the aspects of the tires that keep you happily enjoying your two-wheeled lifestyle. From this brief tire education you should realize that motorcycle tires are more than just a part of the bike, but rather are a crucial component, and though expensive in some cases, represent an investment of the highest order in you and your machine.

Take care of your motorcycle’s tires and they’ll take care of you whenever you ride.

Related Reading

Safety Series: Bike Selection

Riding Safe: Crash Avoidance

Dunlop Sportmax Roadsmart II Tire Review

Dunlop Roadsmart Tire Review

Pirelli Diablo Rosso II Review

Metzeler Roadtec Interact Z8 Tire Review

Pirelli Diablo Rosso Corsa Tire Review

Metzeler Sportec M5 Tire Review

Pirelli Angel ST Tire Review

Michelin Power One Tire Review

Michelin Pilot Power 2CT Tire Review

Metzeler Roadtec Z6 Interact Tire Review

Pirelli Night Dragon Tire Review

Pirelli Diablo Rosso Tire Review

Michelin Pilot Power 2CT

More by Pete Brissette

Comments

Join the conversation